professional factory for Cushion Pad For Pcb Ccl Laminating – Silicone Rubber Cushion For Hot Press – Cayce May

professional factory for Cushion Pad For Pcb Ccl Laminating – Silicone Rubber Cushion For Hot Press – Cayce May Detail:

Product Description

Silicone rubber cushion for hot press is designed and manufactured by our company that is dedicated to supporting the hot press according to market demand, commonly used in the pressing machine pressed laminate flooring, particleboard, plywood, doors, furniture and other occasions.

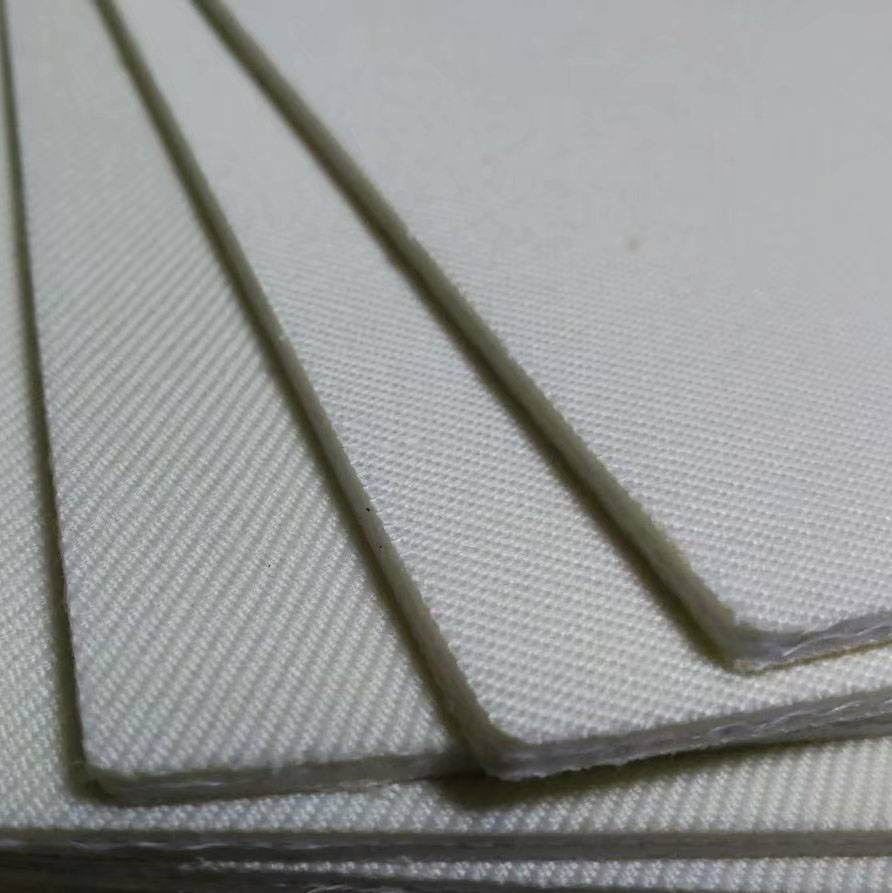

In the working combination of hot press, the silicone rubber cushion is mounted between the hot plate and the template, let the operating pressure and the temperature of the hot plate transmit evenly, then the veneer and the substrate uniformly adhered more closely together, so that it can improve the surface and internal quality of product, can compensate for plate errors to protect the template from damage.

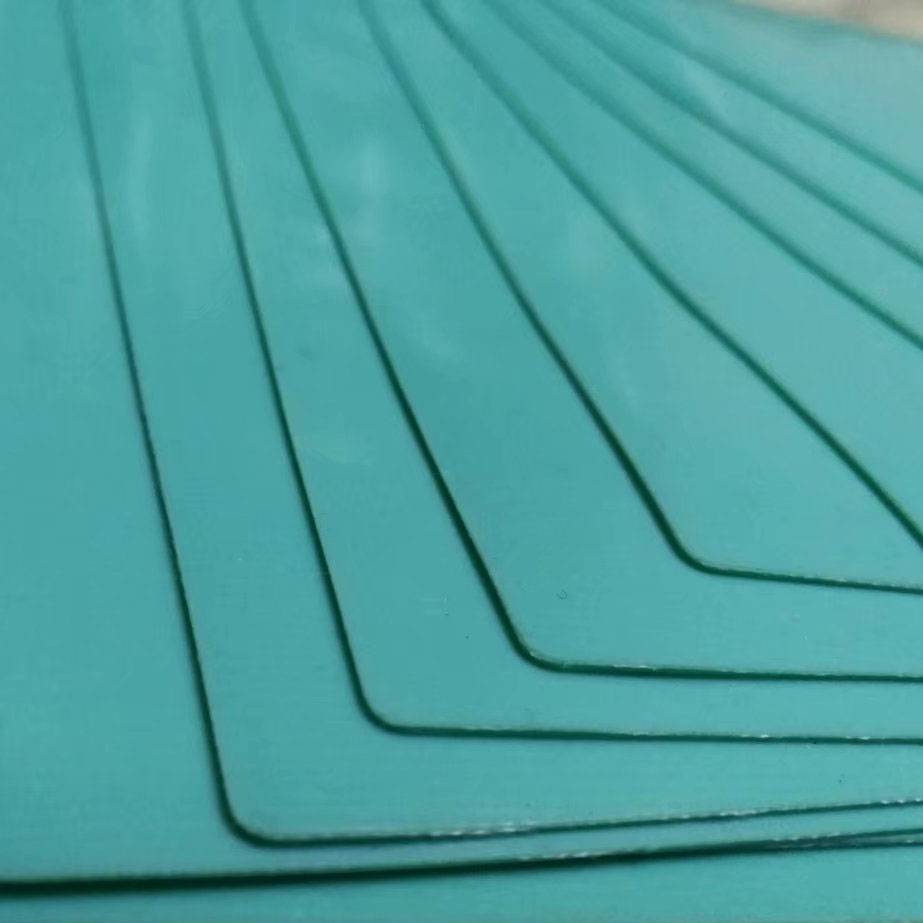

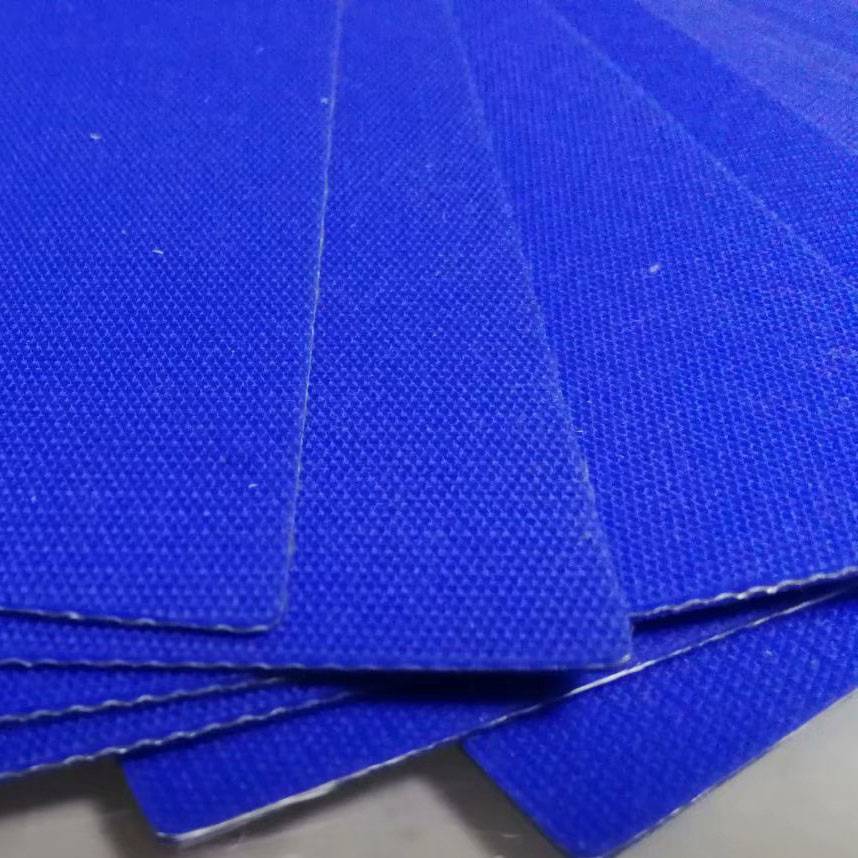

The structure for silicone rubber cushion for hot press is silicone-framework-silicone, the thickness is 1.5-2.5mm, heat temperature 250℃, high tensile and tear strength, no deformation, thickness uniformity, long service life.

Product Details

| Model number | Breaking strength | adhesive force | Hardness(Shore A) | Breaking extensibility % | color |

| Mpa | N/mm | ||||

| KXM2321 | 80 | 2.5 | 55±5 | 350 | red |

Product use: It is used for hot-press, widely used for furniture, wooden doors of the pressure paste.

Product features: high tensile strength and tearing strength, even thickness, long service life, heat resistant up to 250.

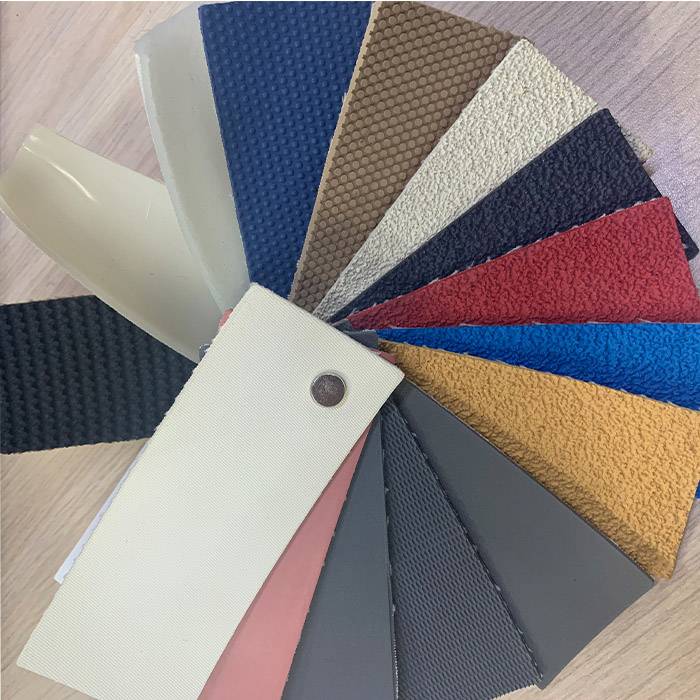

Product specification: 1) thickness: 1.5-2.5mm 2) maximum width: 3800mm with no joint 3) any length 4) color: red

Product detail pictures:

Related Product Guide:

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for professional factory for Cushion Pad For Pcb Ccl Laminating – Silicone Rubber Cushion For Hot Press – Cayce May, The product will supply to all over the world, such as: Greenland, Cyprus, Houston, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for you in China. Of course, other services, like consulting, can be offered too.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.